Why integration of product design and machining is the only way forward.

Software for the furniture manufacturing industry isn’t new, but what is new is the recent emphasis on software integration between the design and the manufacturing processes. To date, product development has been a time consuming and error-prone process made up of several disjointed steps, involving repetition of operations. First the product design is drawn, followed by manual creation of part dimensions whilst taking into consideration edge treatments and jointing requirements. Then the hardware selection is made, part machining calculations worked out and a part release program made out for the prototyping of the product before production. Lastly, the final parts list is documented and the resulting part and product drawings can be produced.

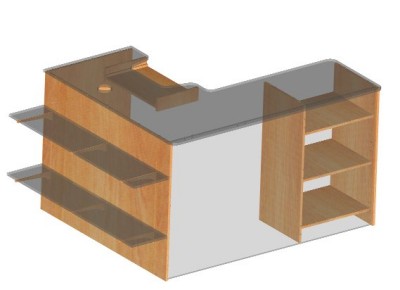

|

| Custom Check-out Desk with glass panels designed in Rapid Engineer & Rendered. |

Too many software products act as ‘islands’, with drawing systems that often do not integrate with each other, so that product drawings are not connected to part drawing, and part drawing is not connected to CNC machining. Many customer-facing design systems focus more on the selling process than on manufacturing, so that there is a big accuracy issue when producing machining instructions.

There is an increasing trend in the market towards more custom-made, bespoke and one-off products, and customers are expecting ever shorter lead times on their orders. They also expect to be shown sophisticated graphics and visuals of the end product – hand drawn designs simply cannot compete. Combine these factors with the changes that are taking place in the industry – manufacturers are carrying lower inventory and moving towards just-in-time manufacturing, CNC machines are becoming ever more powerful but less expensive to buy, making automation a serious option for small and medium-sized companies, and skilled labour is becoming harder to find and more expensive. With PC-based controls allowing easier connectivity, and more powerful industry-specific software available, the need for integrated design and manufacturing software becomes obvious.

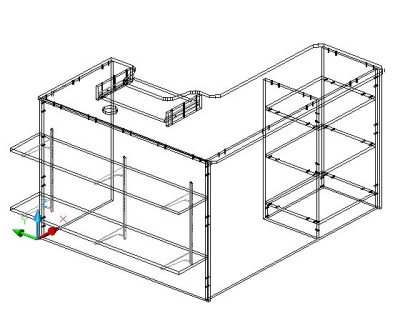

|

| Wire Frame view of Check-out Desk showing construction / machine details. |

Rapid Engineer – streamlining the design process

In recognition of all these factors, Pattern Systems International, the industry’s leading supplier of woodworking software, has developed a powerful new program – Rapid Engineer. Marketed and supported in the UK by Linkwood Software & Systems, Rapid Engineer offers a total solution from design to machine by automating drafting and product design as well as part machining. It is built upon the AutoCAD 2000/2000i/2002 platform, the industry standard for computer aided design (CAD), and is an all-in-one solution for manufacturers of one-off and custom furniture, including

shop fitters, office, laboratory and health furniture suppliers and others.

Rapid Engineer is a true 3D solid modelling program which enables you to design and visualise one-off bespoke products while simultaneously producing part drawings, cut lists and machining instructions in the back ground. All product and part drawings are a by-product of the 3D design, and connecting or adjoining parts ‘know about each other’ – so if one element of the design is changed, the adjoining components will be altered automatically.

Initially parts are designed in 2D not only for shape, but also for how they will connect to adjoining parts when integrated to form a product, without the need to use complex formulae or graphic sets, and stored within a library. During the product design process, as parts are recalled from the library, resized and positioned within the design, matching machining is applied at the connecting points automatically. The same process also works for hardware parts such as hinges and drawer slides. Product drawings allow parts and products to be viewed in rendered form, and illustrate how the parts are integrated with the product by providing front and side elevations, plan views, cross sections with ‘true cross section’ visibility, exploded and 3D views. All parts automatically become CNC ready, and parts are guaranteed to fit. As a result, what were formerly multiple production steps are condensed by Rapid Engineer into a single operator process - thus saving time and reducing possible errors.

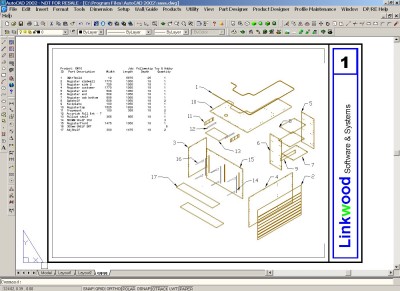

|

| Explode view of 3D Solid Model Check-out Desk. (Click to Enlarge) |

Bob Hockey, Managing Director of Linkwood, is very enthusiastic about the new product. “Because Rapid Engineer has been designed for the woodworking industry, it understands woodworking manufacturing processes and the way parts and products work together, unlike engineering CAD based programs. But it still harnesses the power of AutoCAD and enhances the skills of the AutoCAD operator, so he can simply and effectively design in 3D while creating bills of material, part drawings and CNC machine programs without any extra time or effort.”

As with all products from Linkwood, Rapid Engineer integrates fully with its sister software modules, such as Draw Power, Product Planner and Cut Planner, thereby producing manufacturing information, cut lists, bar-coding labels and CNC parts information machining

geometry for both one-off and custom sized products in an all-encompassing system.