Page 20-22 - No 92 - June 2001

The hard facts of software benefits

LINKWOOD ENGINEERING recently declared that the last financial quarter had been its best ever - a fact made all the more impressive when one hears that the start of the year is usually the quietest period of its annual financial cycle.

It would seem that the company's lengthy experience

in supplying woodworking software is producing dividends at present.

Originally established as an engineering

consultancy business for the woodworking industry, 1986 proved a

significant turning point in Linkwood's history with an introduction to

Pattern Systems, woodworking's largest software developer, based in the

US. Linkwood became the UK agent supplying kitchen, bedroom, bathroom

and office furniture manufacturers, in addition to those involved in

shop fitting, door and window production, and has developed this

partnership throughout the intervening period.

|

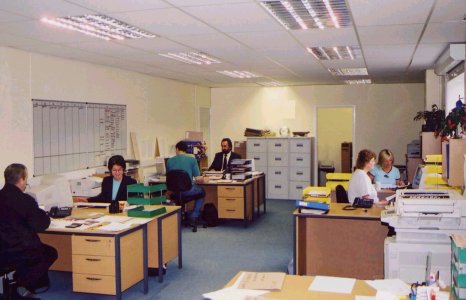

| The busy production planning office at Manor Cabinets, another Linkwood customer benefiting from its comprehensive software services. |

The close relationship between the two companies

has seen many improvements and developments, with the software moving to

Windows and Linkwood developing its own Sales Order Processing and Stock

Control Scheduling programs for use within Product Planner and Cut

Planner.

Since the beginning of the year, all products are available in networked versions with the introduction of software locking, which prevents unauthorised access. this means that all plug-in devices have been superseded, and has resulted in the end of the road for the dongle (a plug-in that enables access to specific software applications).

Full training, implementation and support is available throughout the UK for all products supplied by the company, either in-house or at the customer's premises, and it is important to make a distinction between these. Training provides the knowledge of how to operate the product, implementation is how to use the product to best suit the user's needs. Linkwood offers both and has the field technicians to deliver.

The time difference between the UK and US - often seen as a negative aspect in transatlantic dealings - works to the client's advantage, because any customer requiting assistance after office hours is able to use the American office for expert advice.

Linkwood's presence at Woodmex last year and the development of its website are two of the factors that have led to the recent increase in sales. Having experienced many slow and ineffective web presences in the past, I was delighted to find that this particular one was quick and easy to access and provided a wealth of useful information in an attractive format.

|

|

Instructions can be downloaded direct to manufacturing equipment. |

The company is now able to supply the entire spectrum of administration, design and manufacturing software options to satisfy the many and varied requirements of the furniture production industry. Having spoken with Bob Hockey, founder and managing director, and several of Linkwood's customers, adaptability was the catchword that caught my attention. Having heard from Bob that businesses of any size in the industry could benefit from the introduction of one or all of the software options available, I found that this was endorsed by all of the company's clients that I was able to speak to. Without exception 1 heard how Linkwood's software had become indispensable.

Albert Richardson of Cavendish Kitchens and Bedrooms, told how software supplied by Linkwood ran its entire production department, and was involved in all components of each and every job-"You get out what you put into it," says Albert. “The program is fantastic!"

Chris Williams, managing director of Eborcraft, began with the DOS version of Cut Planner 20,upgraded to the Windows-based Cut Planner 30, and has since purchased Product Planner to assist production of office furniture. "The optimisation of our saw was a vast step forward," Chris told me. "Product Planner is still being implemented, but I'm sure it will work when all the Eborcraft-associated problems have been sorted out."

Crabtree Kitchens used to produce all cutting lists by hand, but this lengthy and laborious process has been replaced. Richard Morley told me how dimensioned cutting lists for all components are now produced quickly and efficiently to assist in manufacturing bespoke, hand-made kitchens: "lt does the Job for me. We're now looking at our next development, a CNC carcass machine.”

Phil Durrant, production manager of Techspec, described how Product Planner enabled the company to easily incorporate alterations to its standard products for individual customers. Techspec had used the software for 2˝ years. “We've only needed support on the odd occasion," Phil stated, "but Linkwood have supplied help whenever it was needed. For instance a recurring problem was reported and we received an e-mail the following day which was downloaded immediately and rectified the problem."

The overall message was that once the basic concept had been understood, and the training completed, the savings in time and materials quickly became apparent. My impression was that the higher the level of software involvement, the greater the perceived benefits and therefore the level of dependency.

The latter is presumably one of the reasons that have led to the company reporting that it has sold more total solutions than ever this year. This task is obviously made much easier by the fact that the software packages connect to virtually all CNC saws and drills.

There is a positive, constructive relationship with many - if not all - of the world's many manufacturers of woodworking machinery, which again means that integration between software and machine is a smooth process.

There is no such thing as a standard furniture manufacturing company. Every firm has different requirements, with varying levels of staffing, machinery, production techniques and factory set-up - compounded by the diversity of manufacturing which includes everything from small workshops producing bespoke items to extensive sites devoted to volume production of office furniture. The range of software available from Linkwood caters for all these needs and can be customised to suit the customer's methods.

|

| Linkwood has an attractive and informative web presence. |

My visit proved timely from yet another perspective, because it coincided with the announcement of the introduction of a major new product. RapidEngineer provides the ability to create custom, one-offs and prototype products, and is described by Bob Hockey as "the direction in which most of the UK furniture industry will eventually go".

This product is AutoCAD-based, and has the ability to produce complete, machine-ready, products - saving vast amounts of time from conventional means - with full integration of all CNC machinery production. The user-defined library of component parts, automatic creation of all cutting, drilling and routing lists and production of DXF files all combine to encompass the spectrum of manufacturing requirements.

The ability to create new products quickly and easily and apply part machining in one virtual manufacturing step is a process which the company claims will revolutionise the method of product design, means compared with the current methods of engineering products, which are cumbersome and error prone, compounded by time consuming methods requiring interpretation of drawings and concepts by various people, RapidEngineer offers many benefits.

The new application offers faster product design, requires the involvement of fewer people and significantly reduces the incidence of mistakes through miscalculation. Automatic machining means that calculations to locate the various part connections of components becomes a thing of the past. Any alterations to the initial design can be quickly and easily incorporated, avoiding complicated and involved procedures necessary when creating products manually. Although as mentioned previously, there is no such thing as a typical furniture producer, the profile of the standard Linkwood Engineering customer is a medium-sized manufacturer, which is often forced to compete with larger companies. However, the company offers a variety of options aimed at serving all from the smallest to largest manufacturers. "Medium-sized companies often products, because they suddenly gain the advantages previously available to much larger concerns," Bob informed me - “People often don't realise the power of what they are getting until after they buy. But when everything is up and running, the advantages quickly become apparent."

It was Bob Hockey's last remark, however, which emphasised his confidence in Linkwood's and Pattern Systems' products and services. As he handed me a list of customers he uttered the words: “Our customers are our best salesmen'"- a phrase which would sit very nicely within the company's promotional material.

• Dennis Flower, Furniture Production, June