![]()

![]()

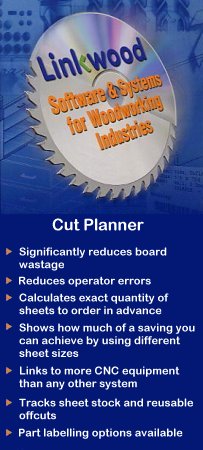

Cut

Planner is an established sheet optimising system detailing the best possible

way to cut rectangular parts out of any type of sheet material. Whether

you use a simple panel saw or the most current CNC cutting equipment, Cut

Planner will save you money on sheet costs and will improve your cutting

productivity.

Cut

Planner is an established sheet optimising system detailing the best possible

way to cut rectangular parts out of any type of sheet material. Whether

you use a simple panel saw or the most current CNC cutting equipment, Cut

Planner will save you money on sheet costs and will improve your cutting

productivity.

How Cut Planner Works:

To create optimised cutting patterns, Cut Planner needs the following:

1) A list of part sizes to be cut.

This parts list my be entered directly into Cut Planner using the keyboard, or a file containing the parts list can be imported into Cut Planner using data created by numerous applications such as Product Planner or Inventory Control etc. Not only the sizes of the parts can be passed into Cut Planner, but also important information such as grain direction, part priority, part description, job name, edge banding details and material type can also be stored and used by the system.

2) A Sheet Material

Inventory.

2) A Sheet Material

Inventory.

The sheets are stored and retrieved from an Inventory Sheet Maintenance System. This system stores the material types and sheet sizes that you might use in normal operation. Inventory Control includes automatic reorder reports generated as the sheet stock drops below reorder levels. Reusable off cuts from previous cut lists can be recycled back into the sheet stock for later use.

3) Cutting Rules

The Cutting Rules tells the system details of your cutting equipment (e.g saw type, saw blade thickness etc), also the complexity of the cutting patterns produced are controlled in the rules area.

A version to suit your needs.

We realise that not every cutting operation works the same way or needs the same information. The requirements depend on the type of cutting equipment, size of operation and volume of cutting. As a result, 3 levels of Cut Planner have been developed to fit the specific needs of everyone.

Cut Planner 10 was designed for small cutting operations that cut low volume parts on manual equipment. Its primary focus is to produce high yield cutting layouts that make the most of your material.

Cut Planner 20 was developed for medium sized cutting operations that cut both high and low volume parts, usually on larger equipment (including single line CNC beam saws). It includes all the features of Cut Planner 10 plus more control on pattern layout to product high yields as well as maximum cutting efficiency.

Cut Planner 30 is the ultimate optimiser that contains all the necessary controls needed to handle large-scale, high volume cutting operations with single line or angular panel saws. Cut Planner 30 contains all the features of Cut Planners 10 and 20 (plus many more) as well as the ability to edit the patterns manually.

For

professional advice on choosing the right version of Cut Planner to suit your

needs, please contact us here.

Note: Cut Planner &

Product Planner are registered trade names of Pattern Systems International